Circumferential Driller

The AIT circumferential drilling machine was manufactured specifically to speed the intensive process of drilling thousands of holes around the aircraft to join fuselage sections – all with incredible accuracy. What once took days can now be accomplished in hours with AIT’s precision-engineered technology.

AIT’s drilling machine was designed using lean manufacturing principles, keeping efficiency in mind. These elements contribute to making it easier to work with, portable, and scalable for any size aircraft.

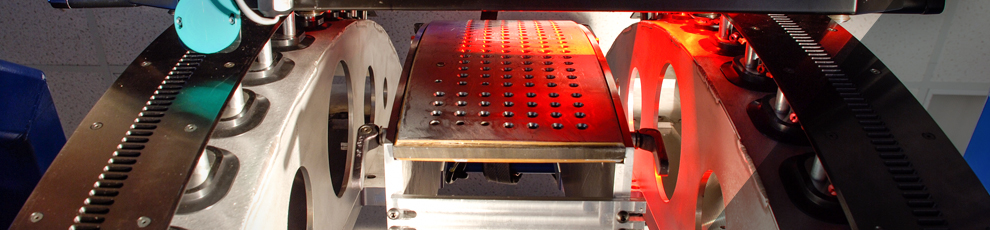

The Drilling Unit

The lightweight unit sits on a dual set of flexible vacuum tracks affixed directly to the plane's fuselage, which conforms to the shape of the airplane. During drilling, the unit rides along the track system, which also stabilizes the drilling unit and ensures accurate positioning throughout the entire process. This engineered precision means substantially better quality and reduced rework for our customers -- all equating to less time and money spent overall.

The carriage assembly accurately positions the drilling head in X and Y axes, using servo control closed loop feedback. The drilling head consists of a spindle with an HSK-A32C tool holder interface and an integrated vision system, which performs machine-to-part referencing and executes AIT scan-and-correct vision algorithms. It also offers optional through the bit coolant delivery, and a pressure foot that provides part clamp up, and skin position feedback for precise countersink control.

See these projects for additional AIT circumferential drilling experience:

Advanced Integration Technology > Solutions > Circumferential Driller

Advanced Integration Technology > Solutions > Circumferential Driller