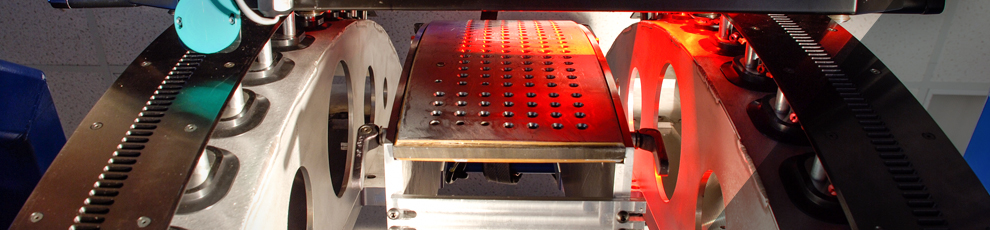

friction stir welding

Friction Stir Welding (FSW) is a solid state joining process that produces improved joint properties as compared to conventional fusion welding techniques.

Fusion welding is characterized by melting of the material, adding a filler rod, and natural cooling to form a weld. A shielding gas is required to protect the weld from contamination. FSW is accomplished at temperatures below the melting point of the material, and neither introduces filler rod nor requires shielding gas to form the joint.

By its nature, FSW eliminates problems associated with cooling from the melted condition such as porosity, solidification cracking and shrinkage. In comparison, FSW has been found to produce nearly defect free joints.

Click HERE for additional information.

Advanced Integration Technology > Solutions > Friction Stir Welding

Advanced Integration Technology > Solutions > Friction Stir Welding